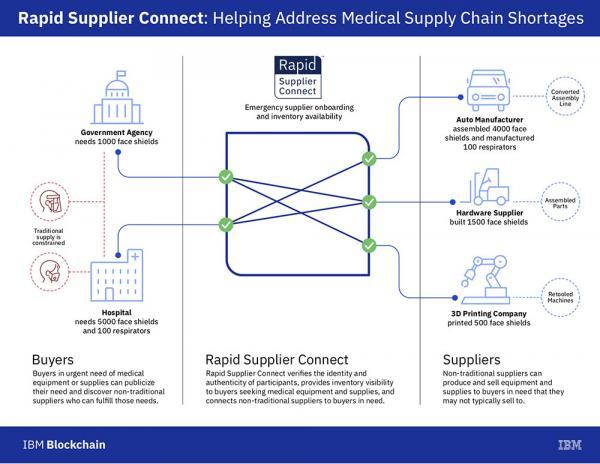

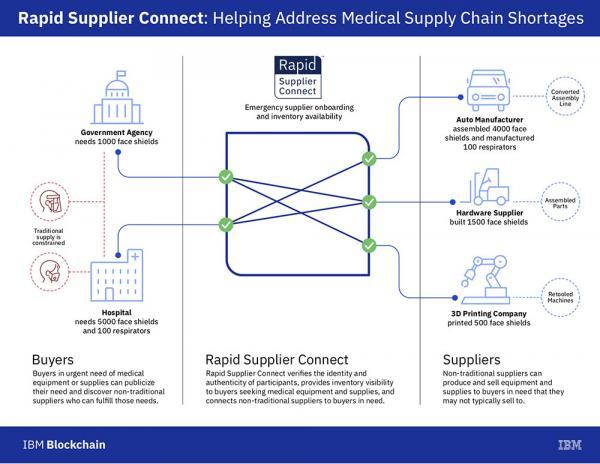

Real-time insight into a volatile and uncertain supply chain is never simple, and with the challenges of the current global situation, IBM harnessed the Trust Your Supplier blockchain-based identity platform built by Chainyard™ for qualification and identification, in conjunction with its existing Sterling Supply Chain Suite and highly scalable Inventory Visibility microservice to deliver this increased visibility.

This article was originally published at Linkedin

The Covid-19 pandemic has caught the entire world by surprise causing widespread destruction in the public health care apparatus including sickness and death, disruption of the economy and the global supply chain, and the everyday way of life of the common individual. No one would have imagined that hand sanitizers and masks would become an essential items to stock at home or carrying vast supplies of face masks and ventilators at hospitals. It also revealed that reliance on one single country as the intermediary and sole source for all the supply chain needs can bring entire companies to a standstill.

The disruption in supply chain has given rise to fraudulent enterprises dumping fake products into the market, price gouging of basic essential items and creating an artificial shortage of groceries, food and essential commodities. A bustling and vibrant economy like the United States has been brought to its knees in a span of a few weeks with soaring unemployment at over 6 million and a government bailout in trillions of dollars.

Not all is bad as the pandemic has had some positive side effects too. The air quality across the globe has improved. Beijing has seen clear blue skies after many years, residents of Jalandhar in India were given incredible views of the Himalayan Dhauladhar range not seen in many decades, the importance of sanitary habits and keeping the environment clean has been realized by many populations and the honking of vehicles has dimmed to give one the melody of chirping music.

I have been watching all the daily White House briefings, plenty of news, thousands of WhatsApp forwards, and reading many articles about the crisis. The focus of this blog is on what are the possible post-Covid-19 impacts and the role of technology, including how Chainyard is contributing. With every crisis, there is new opportunity as many have written. Ali.com, JD.com, Uber, Venmo, Netflix, Airbnb, Groupon have all been born during down turns.

In my opinion a few key technology areas that include Blockchain, AI/ML, Hybrid Mobile Apps and IoT will play a significant role in shaping the post pandemic decade. As the economy readies to reopen, we are already seeing some changes. For example, Emirates is requiring passengers to have blood tests as a requirement, while some governments are contemplating proof-of-immunization to go back to work or get entry into public facilities.

Let us briefly explore how technology is or will play a role in future.

The blockchain provides key capabilities such as

Several solutions that leverage self-sovereign digital identity, track and trace, and supply chain are already in development or existing solutions are being modified. Chainyard, IBM, Evernym, VitalHub, Emerge, Nym, Public Health Blockchain Consortium, Hyperchain, SpreadLoveNotCorona, Mediledger are few of the companies that are engaged in blockchain based solutions. These include anything from contact tracing, distribution of donations, securing individual privacy and traceability of pharmaceutical products in the supply chain. Self-sovereign identity will play a key role where individuals will be responsible for managing their identity and claims, and providing proofs to substantiate them.

AI is being used to sift through various past research on molecular compounds and their past behavior to identify potential cures. AI and chat-bots assist the public by answering questions about the Covid-19 testing and treatments, providing insights and making recommendations. They can be effectively utilized in tele-medicine, remote diagnostics, research on new cures and predicting future outbreaks and their mitigation.

AI has been successfully exploited to identify patterns in the spread and predict the impact of the Covid-19 virus by combining publicly available data, government and other private sources, social, hospital and GIS information. Many companies are offering dashboards and insights. Notable ones I have been following are Johns Hopkins, University of Virginia and SAS.

Claim-8, a company I got to know that has gone further by overlaying Covid-19 analytics including additional data generated by existing super-clusters of computation to develop indices and derivative products that generate human actionable outcomes to provide supply chain insights in addition to Covid-19 related dashboard information. MiPasa, an initiative kicked off by Hacera along with IBM and Oracle is aggregating data on a global scale from various sources to provide insights that enable a swift and more precise early detection of Covid-19 carriers and infection hot spots.

IoT devices can work in concert with Blockchain, AI and mobile technology to deliver a connected experience on a trust platform. I would not be surprised if the security scanners at airports such as magnetometers and x-rays are augmented to include healthcare sensors like digital infrared thermometers, or the enhanced fingerprint kiosks to additionally measure body temperature, conduct instant blood tests and perform contact analysis. Connected digital infrared thermometers combined with AI could provide visualizations about hot spots or emerging outbreaks and provide alerts to hospitals and patients. Ramco Systems has announced a solution that combines bio-metrics and temperature sensors. Sensors combining facial recognition, clock time and temperature are used to enable employee access to the workplace via the security doors.

Theseus from Emerge and Claim-8 from NewBureau are both working on supply chain solutions that track, trace, and optimize the global movement of goods to prevent fraud and counterfeiting. They combine QR tags, RFID, and smart sensors to achieve complete and near-real time visibility into shipments from manufacturer to final destination. Smart contracts validate data from sensors on cargo as the freight moves to detect violations of geo-fence, altitude, tilt, light exposure, acceleration, force, temperature etc. and send notifications about the shipment.

Wearable technology such as those from Oura or CloudMinds are being tested to understand the individual’s health and connect them to healthcare providers and other services. Robots have been deployed to sanitize public spaces, prepare and deliver food and monitor social distancing.

Drones have been able to conduct aerial surveys, deliver food and medicines, sanitize large areas and gather information to support analytics. Kazakhstan is using Terra Drone drones to patrol the capital city during the Covid-19 lockdown. According to a number of sources, Draganfly is working with healthcare data services firms and researchers across to deploy drones in Australia and the US. The proposed “pandemic” drone would be able to fly over people and identify their temperature and respiratory conditions, helping to limit infections.

People carrying digital wallets on their mobile phones to store credentials such as immunization records and virus testing results will become a norm. Quantum Materials Corp (QMC) has a blockchain based QDX HealthID for transparency in disease testing and immunization from infectious diseases. Combining tags using nano-particles which emit different colors when illuminated by light, they authenticate the the individual, the test administrator and test kit, and the immunization record. Chainyard, ProCredEx from HashedHealth, Evernym and many others are testing similar credentialing solutions.

If we were to categorize the areas of impact and what changes can be expected post pandemic era, it will probably look as below.

A specialized blockchain company, providing Hyperledger Fabric and Ethereum based solutions to several Fortune 500 enterprises and our flagship solution “Trust Your Supplier” has already started transforming the way enterprises manage their procurement process. TYS is a joint venture between Chainyard and IBM.

In order to jump in and get involved with the Covid-19 crisis, the first thing we did was to help Miracle, a Volunteer Non-Profit Organization, extend a disaster management solution we had built earlier to have features that enable individuals to register for a Covid-19 test in the app at any of the registered centers within a certain radius to their location. The disaster management solution brought together volunteer organizations, volunteers, resource providers, distribution centers and donations together on a common platform to have efficient communication and distribution of services and goods. Obviously, there are so many families needing supplies such as soap, hand sanitizers, toilet paper etc. and with the lock-downs in place, it is indeed difficult to shop around.

In addition, we are testing another solution based on the Self Sovereign Identity and verifiable credentials protocol to issue or verify claims by individuals about their health. This can enable a number business and public facilities to allow individuals to work or enter public places. Users can simply present a QR Code of their claim that can be scanned by a Relying party to verify the claim and enable services.

Lastly, we are working on a solution that enables “Rapid Covid Response” along with our partners, leveraging our TYS technology that has been in production for quite some months now.

This article was originally published on Forbes.

IBM is turning to their blockchain networks to strengthen their supply chain. IBM Food Trust, TradeLens and Trust Your Supplier are being leveraged during the COVID-19 pandemic to source with trusted suppliers, purchase quality goods, and ensure on time delivery of goods.

This article was originally published on American Express

Successful company leaders in the 21st century fear becoming obsolete. High-profile examples from the past 30 years drive those fears. As an industry, video rental stores are perhaps the most famous example: People once thought these chains too big to fail, but the industry didn’t foresee mail-order rentals and video streaming services as serious competitors to retail business. As a result, brick-and-mortar video retailers have faced a cascade of setbacks that led to bankruptcy for at least one former giant.

Today, blockchain is the technology that’s changing business as we know it. While many companies fear obsolescence, their apprehension about embracing change and emerging technologies may make that fear a self-fulfilling prophecy. We are on the brink of the next technological transformation—now is the time to embrace change and safeguard your business.

Fear of change is far more damaging than the fear of becoming obsolete. Although film and photography companies were quicker than video rental services to join the digital revolution, for example, some companies’ business models struggled to adapt fast enough to thrive in a digital world. Though prominent brands haven’t all disappeared, some have filed bankruptcy and shifted focus to providing services to corporate markets.

Failures like these haven’t just stoked fear for today’s companies, but they’ve also sparked the realization that companies need to be more open to adopting emerging technologies. In a 2018 survey conducted by PwC, 84% of 600 executives from 15 territories say their companies are involved with blockchain to some degree.

As the world embraces blockchain as an immutable data source and identity management system, consumers will start demanding that all companies provide the same privacy-based data systems. Blockchain is built to meet that demand, and a company’s decision to build a network now or join one later is crucial to its long-term ability to be a leader in the new market.

If you’ve hesitated to adopt blockchain, you’re not alone. Every business leader has his or her own unique concerns, but the following reservations are the most common.

As online video streaming was 15 years ago, blockchain is still an emerging technology. It will go through many iterations as it’s tested against market vulnerabilities. According to a 2019 Gartner report, up to 90% of current implementations will have to be replaced within 18 months to keep up with those iterations.

It’s true that early blockchain platforms had to converge and mature before they could be adopted enterprise-wide. Today, however, leading enterprise platforms are in a good state for prototyping business cases and evaluating revenue models with the launch of minimally viable blockchain ecosystems. If companies have realistic expectations about what blockchain can offer them in time, they shouldn’t be apprehensive about making blockchain part of their strategies now.

Because blockchain’s greatest value lies in bringing entire supply chains together, the technology works best when it’s applied across a large consortium of businesses. For companies that aren’t part of or at the head of such a consortium, blockchain technology might seem like a luxury without much benefit.

However, there are many use cases for which blockchain is bringing tremendous value to ecosystems of all sizes. For example, several companies now use IBM’s blockchain to streamline the procurement of contingent labor to reduce overhead in labor management. Such benefits are huge for smaller business networks.

You may see blockchain’s immediate benefits yet doubt its long-term potential. But blockchain isn’t just a new solution to integrate into existing systems. It’s a platform that reduces fundamental data-sharing costs, automates mundane tasks, manages smart contracts and makes room for new revenue-boosting business models.

As the world embraces blockchain as an immutable data source and identity management system, consumers will start demanding that all companies provide the same privacy-based data systems.

Once a blockchain network is populated with members, those new models can be operated on top of it, with early adopters guiding that operation. Many project managers have difficulty visualizing this in the beginning, but a strategic consultant can help companies create a road map for planning and governing the growing network.

One of the biggest reservations that companies have about adopting blockchain is that doing so will require an entirely new way of thinking. Current enterprise resource planning systems may restrict data within company firewalls, while blockchain requires a more open-minded approach. This kind of enterprise-wide cultural shift can take time.

However, the time investment is worth it. In some systems, entities throughout the blockchain ecosystem can submit queries about consumers’ and other businesses’ digital IDs to authenticate transactions. Once companies adopt it, they can substantially reduce the time and money they spend on record keeping and authentication procedures while facilitating adherence to regulatory requirements.

Those who hesitate to adopt blockchain may miss out on becoming network builders and reaping the benefits that come with leading a consortium. They may be left scrambling to join an already thriving network once doing so becomes absolutely necessary.

This article was originally published on ManufacturingTomorrow

The power of trust is what binds manufacturers and their distribution channel partners to honor their commitments with each other’s best interests. Lately, however, that trust is strained as revenue growth shrinks across the supply chain.

According to McKinsey & Company, consumer packaged goods manufacturers saw revenue growth drop from 9.7% in 2011 to a dramatically lower 1.2% in 2018. While facing this decline, manufacturers have also contended with retailers’ attempts to stem their own lost revenue; after all, retailers are under pressure to keep up with the same levels of demand or face steep fines for late or incomplete shipments.

Over the last several years, however, blockchain has proven an effective salve for the dwindling trust in today’s supply chains. It enables a network-wide protocol that helps reduce “trust tax,” or the costs of maintaining trust. The cryptographically hashed, consensus-driven data stored on blockchain across multiple nodes provides immutable provenance and audit trails — a single source of truth that becomes the foundation of trust.

We’ve already seen this in action with initiatives such as the IBM Food Trust, a blockchain-powered ecosystem of companies all along the food supply chain. The Food Trust records provenance, builds transparency, and engenders trust at every stage of each food product’s value chain. The success of such initiatives compels more companies to adopt blockchain and the Internet of Things. This year, trusted real-time data sharing will take a huge step toward becoming the norm.

Although fewer than 5% of the highest-grossing manufacturing companies piloted Industry 4.0 projects with blockchain in 2018, that number is projected to jump to 30% by 2023. Likewise, some experts predict the market for blockchain in manufacturing will exceed $566 million by 2025.

Adoption will continue to accelerate in 2020 as manufacturers implement blockchain solutions to streamline operations. Some manufacturers seek more visibility into their supply chains, and others focus on tracking assets with enhanced precision and timing. As each solution excels at its purpose, blockchain’s overall potential to foster trust across both objectives will become increasingly valuable.

Some major features rolling out include transparent supply chain monitoring and digital supplier identity and management (think the Trust Your Supplier platform). In another example, Circulor recently used Hyperledger’s blockchain to ensure complete mine-to-manufacturer traceability for a conflict mineral mined in Rwanda.

In another Hyperledger application, Honeywell Aerospace launched an Amazon-like service dedicated to warranty management, components tracking, and regulatory compliance on the sale of used aircraft parts. In less than a year, more than 50 vendors have used the marketplace, which sets a higher standard of trust than we’ve seen in recent years.

The trust that current blockchain-based manufacturing applications can generate will be especially important this year as the space continues to mature and innovate. To make this transition easier to manage, many companies now offer blockchain solutions as a service to manufacturers in the ecosystem.

Like other software-as-a-service solutions, companies can sign on for provenance, traceability, and/or warranty management as separate services rather than building their own blockchain networks. The key innovation, however, is the combination of IoT and artificial intelligence with blockchain technology to provide real-time data and improve forecasting.

Most blockchain solutions automatically collect immutable data regarding operational conditions such as temperature changes or normal wear and tear. Adding AI on top of this data provides analytics that companies can trust to guide their policies and decision-making processes.

Blockchain solutions now pave the way toward greater implementation. Using traditional blockchain technology requires bringing on talent to manage its capabilities, database, security, privacy, and network. Further, blockchain requires policy to ensure governance among stakeholders using the solution.

Blockchain solutions allow enterprises to enter the value pyramid at a measured pace, which helps encourage buy-in across an organization. The typical value pyramid includes a foundation of integrating and sharing data, a smart contract layer in the middle, and — the ultimate goal — an innovation of business models at the top.

Before you can reach the innovation stage, you should prepare for the inevitable changes coming to blockchain in manufacturing. Use these five tips to get ahead:

Whether blockchain works as a service or as an entirely new business model, it’s already a significant part of the manufacturing industry. Before long, the power of trust that binds manufacturers and their supply chains will rest securely in blockchain-powered ecosystems.

First Hyperledger project to hit 2.0 milestone, raises the bar for enterprise blockchain. New release optimized for production deployments with decentralized chaincode features, private data enhancements, and improved performance

Let’s take a peek at some of the highlights of Fabric v2.0….

This article was originally published on Linkedin

Every year, the United States experiences disasters with varying impacts to the community and the economy. These disasters include hurricanes, tornadoes, wildfires, floods, snow storms and mud slides. While some disasters are predictable as to when they could occur, the location of the impact, the cost of recovery and the time to recover are often difficult to estimate. For example, Hurricane Mathew, one of the most powerful hurricanes to inflict severe damage to Haiti, made its final landfall in the state of North Carolina. The hurricane damaged or destroyed as many as 98,000 homes in Eastern North Carolina and nearly 20,000 businesses. It also damaged roads and water supply and waste treatment systems. Since the storm, nearly 4,000 homeowners applied for hazard mitigation grants. As per the CDC, contributing to the devastation wrought by Matthew was the fact that the hardest hit areas were also the poorest counties in the state, with consistently the worst health problems and poorest health infrastructure.

The impact to affected communities is tremendous and takes years to rebuild requiring plenty of resources. Today, such disasters are managed through an informal collaboration between volunteer organizations, relief organizations, public and corporate support, and government agencies. While all efforts are noble, there are various operational challenges that can be improved including registering volunteers, internal co-ordination within large agencies, external co-ordination across organizations, collection and distribution efforts, and recording of transactions across all of the efforts. Donors who wish to donate their time and resources, including money, do not have a single channel or process to do so. Additionally, others are hesitant to participate due to a lack of transparency, trust and efficiency in the process. In the aftermath of hurricane Mathew, the CDC coordinated all of the emergency activities from the state’s emergency operations center, or EOC, where 16 PHEP-funded staff logged 921 hours. Additionally, due to preexisting relationships with surrounding states, the state was able to request and receive 20 public health nurses from Tennessee within three hours.

Several volunteer organizations engage in Social Work across the globe and often go by “NGO or Non-Governmental Organization”. NGOs have a mission and vision to create social impact among deprived and needy communities. Some of the NGO Projects are long term such as providing sanitation and clean drinking water. Others are based on events such as disasters caused by hurricanes, forest fires, etc. NGOs are supported by various donors, organizations and volunteers who contribute time and resources. These resources can be in the form of money and non-monetary material contributions. Volunteers register with NGOs to deliver services to the communities they serve. Some volunteers provide access to their vehicles while others help in performing work and/or delivering the supplies to the impacted community and areas.

Key issues facing donors and NGOs include

Any relief effort involves collaboration between various parties. The following graphic shows the various parties engaged in a disaster relief and management process.

It is obvious that they all have to collaborate ultimately to provide relief to the needy and affected communities.

The Miracle Relief Collaboration League (MRCL, www.mrcl.org) is a non-governmental volunteer organization that engages in natural disaster relief efforts such as hurricanes and floods. Chainyard had the experience of working with Miracle to enable a blockchain based solution.

There are many reasons, why a blockchain enabled solution makes sense as listed below.

The Chainyard team worked with Miracle Leadership and Volunteers (some of them were IBM employees) to build a blockchain based solution that replaced the old MS Access application. The architecture was based on the Hyperledger Fabric and the solution was deployed for piloting on the Google Cloud.

While designing the solution, one of the goals was to address key existing pain points and gaps. Coordination and communication between relief coordinators, and with those needing assistance was very important. Second, visibility into the inventory of supplies and their proximity to affected areas was major. Third, the ability to match needs of the affected party to available supplies was essential. Finally, since PII information such as name, phone, address etc. are collected, the solution had to provide for privacy and anonymity of transactions.

One critical aspect that the solution had to enable was the ability to record a request for help or any communication from anywhere using a smart phone as long as connectivity was available. The graphic below shows a sample screen from the application.

The highlights of the solution are as follows:

The solution was well received from a corporate social responsibility and community outreach perspective, and was awarded the 2019 Stevie Award.

Chainyard specializes in advising and supporting small, medium and enterprise companies in Blockchain. Because we work closely with members of the Hyperledger foundation and are actively involved in the Blockchain community, we’re able to provide our clients with expert insight into the Blockchain landscape to determine the most valuable Blockchain solution implementation for your business.

Chainyard had a team of five who closely worked with Kathryn Ingerly, Derek Harrison and Lee Duncan. This technical development of this project was sponsored by Sai Nidamarty as part of Chainyard’s Corporate Social Responsibility initiative.

This article was originally published on Linkedin

This is the third in the initial series of five articles. The first article provided a high-level setting for the role of blockchain in supply chain. The second one deals with the concept of DID (digital identities) and verifiable claims. Now, we will explore supply chain issues around fraud and counterfeiting, and how blockchain can address some of them.

There are many posts on Fraud and Counterfeiting (F&C) of high value, branded items and luxury goods such as Gucci, Coach, LVMH, Prada and the likes. F&C costs the economy billions of dollars in revenue loss annually and impacts the reputation of the brands themselves. The issue is not just confined to luxury items, but includes a broad range of high value items such as expensive wines, watches, jewelry, drugs and medicines, art and so many more.

According to the FDA, counterfeit medicine is fake medicine. It may be contaminated or possibly contain wrong or inactive ingredients. Unfortunately, counterfeiting drugs and medicines has become a lucrative business. These fraudulent drugs often originate overseas or through internet pharmacies where counterfeiters are able to inject fake antibiotics or medication into the supply chain and sell them to unsuspecting consumers, and this problem is global. Other types of fakes include having the right active ingredient, but wrong dosage, mislabeling expired medicines or near-identical reproduction of the labels affixed to counterfeit medicines. Medicines lose their effectiveness when they go past the expiry date or are not handled in accordance with manufacturer’s specification.

Many supply chain participants, distributors, retailers and customers are very interested in ensuring that the product they supply, or buy is authentic, and that they get the maximum value for their purchase or investment. However, many buyers who do not have the money willingly go with the fakes and fall victim to sellers who intentionally stock knockoffs to cash in on the high margins. These are criminal activities require the use of more sophisticated crime fighting technologies.

Brand manufacturers apply signatures to luxury goods to ensure that the product is authentic. Several websites offer tips on how to recognize a counterfeit by parsing through these signatures. There are a variety of characteristics buyers are advised to look for to authenticate their products such as the zipper style, material, logo size font & placement, embossed stamps, information tags & inserts, provenance marks (such as “Made in the USA”), lining, dust bags and serial numbers. There are similar signatures that apply to clothing and other luxury items.

In the case of drugs, pharmaceutical companies offer guidance on detecting fakes on their websites. The Bayer website has good information on detecting counterfeit drugs.

Major brand owners are now partnering with technology firms to implement solutions. For example, Microsoft, Consensys and LVMH recently announced a consortium with Aura Ledger. Christie’s is teaming up with blockchain-secured art registry service Artory.

In the case of pharmaceuticals, the Drug Supply Chain Security Act (DSCSA) outlines steps to build an electronic, interoperable system to identify and trace certain prescription drugs as they are distributed in the United States. This is expected to enhance the FDA’s ability to help protect consumers from exposure to drugs that may be counterfeit, stolen, contaminated, or otherwise harmful. T-Systems and Zebra Technologies are using IoT and secure tagging to fight fraud committed in the supply chain processes.

Retailers like eBay and “Legos in my Louis” offer online product authentication services as a value-added service. DHL Resilience360 (a supply chain risk management platform) provides end-to-end supply chain visibility of pharma lifecycle from manufacturing to distribution. Entrupy and Goat are helping consumers identify fakes in high-value branded items using AI/ML, deep learning and computer vision to process millions of pre-stored micro-images about products against user taken ones.

The following diagram shows a generic supply chain flow. A company designs products and then manufactures them by either using their own factories or contract manufacturers. The company operates a supply chain preparing quotes, capturing orders and full-filling them through the chain to meet the needs of their buyers. The intermediate participants in this process include logistics, in-bound and out-bound customs (if cross border), transporters, freight forwarders, warehouses, and distribution centers (both local and remote), among others. Ultimately the product ends up in retail stores and is available to consumers.

Most contract manufacturers are located in Asia where controls are lax and oversight is minimal. It does not take much to steal a few originals and replace them with fakes. It is conceivable that fraud can be committed at several points along the supply chain. Counterfeit products can be swapped for genuine ones or injected at several points in the route.

If this supply chain was moving pharmaceutical products, there is potential for inappropriate handling or exposure to abnormal conditions. Improper handling of goods can result in the damage to the goods, and if such goods are not properly tracked and removed from the chain, could lead to reputation loss and potential lawsuits. Additionally, even if those goods were moved out of the supply chain, fraudsters can move them back into the markets.

Several factors determine the choice of the architecture and implementation strategy. An organization can be influenced by various risk factors:

The following graphic shows the choice of technology and architecture stack in relation to cost and effort.

The architecture stack should enable all participants in the network to collaborate, instill trust and transparency into the system and ensure that the consumer connectivity and confidence. As the stack grows, the complexity of the implementation increases and is visible in both cost and effort.

Technology elements that are fundamental and key to help build a robust solution include Tags, AI/ML, Blockchain and IOT. Let us examine each of these.

A distributed ledger technology that enables organizations to participate and execute transactions in a decentralized environment, where data is stored in an immutable ledger. The blockchain provides native support for transparency and privacy, and enforces trust through a consensus protocol. Blockchains are classified as permissioned, public and fit for purpose. The two most popular technologies in the market today are Hyperledger, for permissioned blockchain solutions, and Ethereum for public & private crypto driven solutions. Within the Hyperledger family, Indy is a “Fit for Purpose” blockchain to manage individual or corporate identities. The choice of blockchain technology is dependent upon the use case and the capabilities that the platform must provide natively.

A tag is a label attached to a product containing or providing information. A tag can be electronic or printed and usually read using scanners, mobile applications or electronic detection systems. The most common tags used are bar-codes and QR-codes, but there are other tagging technologies available today.

RFID Tags have been around for a long time and have two parts: an IC (integrated circuit ) for storing and processing information, and an antenna for retrieving and transmitting data. RFID technology uses readers to bounce off signals on the RFID tag and read information stored within the tag.

Each product can have a unique ID, such as an Electronic Product Code (EPC), and be read without being in line of sight of the reader. This allows the chip to be embedded into an asset. In terms of security, RFID tags use one of many ways such as challenge-response authentication ( CRA ) and “shielding” to prevent information from being hacked.

NFC tags are small integrated circuits, either square or circular, designed to store information that can be retrieved by NFC-enabled devices like smartphones and tablets. NFC tags derive their origin from RFIDs in that they are passive devices and do not require native power supply to drive them.

NFC tags can store wide ranges of information, from product identification, short lines of text, web address or contact details. NFC tags can be secured so that once data has been written, it cannot be tampered. NXP manufactures a range of tags with features like authentication, memory protection, encryption and tamper detection. When combined with IoT devices, these new tags can enable smart sensors.

Copy or Tamper proof tags are companies like Scan Trust, Veritrace, Verinetics and Zortag. These tags have some additional digital information that prohibit the tag from being copied. Zortag uses a combo of a 2 dimensional and 3 dimensional print that renders the label impossible to duplicate.

Temperature and light sensitive tags can be applied to pharmaceutical products and provide data on how the product was exposed during the supply chain process. The temperature sensitive ink changes colors based on exposure to light and heat. It is possible to calibrate the effectiveness of the drug based on the color changes of the label.

Micro-Tagging using edible chemical additives, such as highly purified silica and optical signature encoding are available from companies like True Tags.

AI/ML holds tremendous promise and provides new capabilities to tackle traditional problems. In fact, machine learning, artificial intelligence and deep learning have been compared to the Russian Doll, where the smallest piece fits into the next higher piece and so on. RPA or robotic process automation is a key part of ML. RPAs help automate common repetitive workflows, and in addition to speeding up the process, they bring efficiency and discipline in the execution of business rules.

Millions of shipments are received into the country every day. It is impossible to open and check every package for illicit drugs, counterfeit items and prohibited shipments. Machine learning can be used to teach the system such that pattern matching algorithms that can identify shipments that should be opened by creating knowledge graphs using data such as point of origin, shipper, handler(s), handling unit(s), carrier, originating country, manufacturer, factory(s) etc.

The ubiquity of the internet and new innovations in sensor technology make IOT devices an integral part of any supply chain solution. These devices can be discrete or composite and can measure a range of attributes such as temperature, acceleration, exposure to light, altitude, force, velocity, GPS co-ordinates, vibration to name a few. Technology firms have been able to pack a lot of sensors into a small form factor.

Temperature sensors measure changes in temperature against a set threshold and is very useful in drugs and pharmaceuticals logistics.

Photosensitive sensors can be used to check if a packed box was opened during transit, thus notifying the seller or the consumer that a package in transit was opened.

GPS Sensors help in tracking package handling deviations from a prescribed path during the movement of the shipment, thus highlighting potential fraud. A Geo-Fence can be defined around prescribed routes and designated areas and smart logic can calculate diversions.

Vibration, Tilt, Altitude, Pressure, Force and Velocity sensors can provide data on elements such as packaging, transport, handling and delivery

IoT devices are now available to operate in Narrow bands (NB). This allows operations with low power consumption, minimal hardware, leverage wide area networks and existing infrastructure, and NB signals can penetrate concrete walls. This makes them cheap and easily deploy-able. The graphic from Postscapes and Harbor Research presents a visual of the IOT landscape.

All assets, be it a luxury bag, a $1000 bottle of wine or an expensive retro-viral drug, carry identities such as a serial number. A few concepts can be combined to evaluate if an asset can be genuinely protected from fraud. Any approach must be able to address the following concerns.

The key elements are key to defining a solution include secure tags, DID (digital identity), asset token and verifiable claims. Any tagging solution should be physically and digitally verifiable.

The Secure Tag, depending on the technology selected by the company can be the asset ID tag or mapped to the Asset Serial Number. Secure Tags can be generated by the factory or purchased in bulk from a Tag Supplier like Zortag. The factory purchases the secure tags in advance and then assigns them to serialized assets that come out of the production floor. They could assign it by either receiving a bulk file of the Tag Numbers and using the application to do the assignment, or they could use a scanner to scan the Secure Tag and the Product Bar Code to establish the assignment.

A secure tag can be generated using a function by the factory as shown in the example below.

asset_tag = function (signature attributes, tag generation pattern, cryptographic algorithm)

Signature attributes can include a host of elements such as serial number, factory id, manufacturing date, tag supplier etc. The pattern can define how the attributes are processed or the algorithm is applied and the algorithm indicates the crypto processing approach to be used for generating this label. The resulting tag can be printed as a QR code, Bar code, Data Matrix Label, NFC encoded tag or any other form.

The Proof of Ownership is a generated tag that is like the secure tag generation process. It combines various attributes surrounding the sale and embeds certain secrets that the consumer provides.

The DID (discussed in my previous post) can support Proof of Authenticity. Tags can be associated with a DID so that each asset has a unique global self-sovereign identity pointing to verifiable credentials. Verifiable credentials originate from various sources including manufacturers, authenticators, certifying documents etc. One of the verifiable credentials could be a pointer to the certificate of ownership.

Additionally, an asset could be linked to a Digital Token such as a compatible ERC 721 to enable trading and ownership tracking..

A solution could use one or all of the elements depending on the nature of the asset. For assets with short life, a smart tag with a token may be enough. For long living assets, such as fine art, expensive artifacts and luxury goods, a combo may work best. By tying the physical to cryptographically linked assets together, we can have digital and physical protection.

The following diagram shows an architectural view for a solution. We will not delve deep into each element, but describe them at a high level. The core solution must support two types of use cases.

In this architecture, there are three environments:

The Blockchain Environment

The blockchain environment can be a single environment or multiple environments. A permissioned blockchain such as Hyperledger (Fabric, Sawtooth or Iroha) manages all the smart contracts associated with the actual supply chain transactions. These contracts support transactions such as recording and querying products, assigning secure tags to the assets, recording product & product profile signatures, supply chain scans, emitting smart events based on IoT data, and verifying and/or authenticating tags.

In addition, the same permissioned blockchain or an interface with a public chain like Sovrin or uPort could assign DIDs and manage the verifiable credentials supporting the asset. The advantage of DIDs are that they are universally resolvable.

One could optionally tokenize the asset and leverage an ERC 721 supporting platform ,such as Ethereum. Interoperability between the three chains at a business level is very important consideration.

Security is a very important aspect and the blockchain provides the necessary identity and access management for the millions of IOT devices that support the supply chain, secures the data and intelligence that the AI/ML systems generate, and provides role-based access control for all the participants and personas in the ecosystem.

The API Environment

This environment provides a number of APIs as seen in the diagram. The three areas of interest are:

The solution is technology agnostic, providing an environment where multiple scan & tag technologies can coexist with APIs to connect with various external technology clients.

The Client Environment

This is the layer that links all the interfaces into the solution. Most clients that deal with tagging, scanning and authentication are end-user apps that run on mobile devices, desktops or other devices such as scanners. The apps themselves may be many to support the workflow for individual personas – for example a consumer app, a retail POS app and a Supply Chain App.

No solution is complete without integration into enterprise applications. In addition, the architecture should support integration into various third-party technologies for scanning, authenticating and payments.

Lastly, the system supports a variety of IOT devices that keep their senses open during the supply chain process.

The Client Environment

This is the layer that provides all the interfaces into the solution. Most clients that deal with tagging, scanning and authentication are end-user apps that run on mobile devices, desktops or other devices such as scanners. There may be many apps to support the workflow for individual personas – for example a consumer app, a retail POS app and a Supply Chain App.

No solution is complete without integration into enterprise applications. In addition, the architecture supports integration into various third-party technologies for scanning, authenticating and payments.

Lastly, the system supports a variety of IOT devices that keep their senses open during the supply chain process.

Transaction Environment

The participants in this network include the Company, Factory, Logistics Operator, Transporter, Tag Supplier, Retailer and Consumer. At a high level, the system should support the following use cases by persona

There are other elements of the architecture such as the assets, transactions, registries, access controls, integrations and contracts that are not discussed here.

Anti-Fraud and Anti-Counterfeiting can be solved using a combination of various technologies such as Blockchain, Self-sovereign Identity, AI/ML and IOT. The main aspects of the solution fall into track & trace, asset identity management and verifiable credentials.

This article was originally published on FreightWaves.

In 2017, Chainyard partnered with IBM to develop the Trust Your Supplier (TYS) blockchain platform, which launched a couple months ago with 15 participating companies.

“[The platform] is providing a trusted source of supplier information to simplify and accelerate supplier onboarding, lifecycle and management,” said Alex Rosen, vice president of business development at Chainyard, at the 2019 Blockchain in Transport Alliance (BiTA) Symposium in Chicago.

IBM is the first company onboarding suppliers through the system, and it’s saving a tremendous amount of time and money in the supplier onboarding process.

“This network will onboard tens of thousands of suppliers very rapidly because of the types of companies that have committed to use it,” Rosen said.

Headquartered in Morrisville, North Carolina, Chainyard is a consulting and implementation provider that has built over 24 blockchain projects and has four networks currently in production — one of which thousands of users rely on for financial transactions. Chainyard has been in blockchain production for four years, using both Hyperledger and Ethereum. It has 65 employees working on blockchain.

Chainyard’s blockchain solution responds to a common pain point among logistics providers: qualifying hundreds of carriers by validating documentation while managing risk and regulations is a convoluted and inefficient process. Onboarding and updating data is also inefficient when multiple parties are using different databases to manage the same data.

Chainyard built a trusted source of supplier information and digital identity (DID). The DID allows for persistent identities, meaning they don’t change over time; they’re cryptographically verifiable, decentralized and universally dissolvable.

“What we implement on TYS is self-sovereign identity (SSI) but for organizations,” said Mohan Venkataraman, Chainyard’s chief technology officer. “SSI is a mechanism by which the organization, individual or item holds the identity and can share and manage. TYS is seen as a digital passport for suppliers.”

Chainyard put together a network not just for suppliers and buyers, but for other parties like verifiers and insurers. While the supplier holds the DID, the insurer issues credentials to the supplier. The verifier validates those credentials, and the buyer is then able to trust the supplier. The credentials could be a university degree, a business license or insurance issued.

“TYS is all about qualifying the supplier and business partner by answering questionnaires on various topics, whether its diversity, environmental compliance or financial compliance,” Venkataraman said. “It also stores verifications from third parties, whether it’s verifying that the DMV number or address is correct.”

Building a blockchain network, Rosen said, is the biggest upfront challenge, but once the system begins to scale, the challenges become more technical. What’s imperative is making sure each player in the ecosystem — shippers, recipients, consignees, payers, brokers, carriers and logistics providers — finds value in the network.

“How TYS works is, we classify business objects into two zones: off-chain and blockchain,” Venkataraman said.

The off-chain zone is where they maintain data that’s necessary to keep but is not revealed on the blockchain. This data consists of member credentials data, personally identifiable data and application-specific data.

On the other side, blockchain data consists of publicly shared supplier data visible to all parties. Privately shared supplier data will be visible to two parties that have a contractual relationship. Public securely shared data can be selectively shared publicly.

“This looks like a regular application,” Rosen said. “If you’re using the application, you would not think that it’s blockchain. Under the covers, however, there’s a body of these companies that are working together to govern the dataset.”

This article was originally published on LinkedIn.

Creating a good demand forecasting system is a major challenge because it’s so hard to get trusted data. The difficulty is compounded by suboptimal sales forecasting — another symptom of siloed business data.

Good forecasting requires quality analytics, and that’s only possible with access to data from various sources, both internal and external. When every business in your supply chain handles data differently, the discrepancies lead to duplicative, often incorrect data that seriously impedes efficiency. That’s especially true for companies that have built up their ERP and CRM systems piecemeal over the years, using different systems for each.

With so many disparate systems, how can you ensure that the data you receive is trustworthy? There’s no way to know who validated it, nor a means of determining whether the data is consistent up and down the supply chain. Many manufacturers are turning to blockchain to close these gaps and ensure that all data can be trusted. Yet many still face barriers, as implementing an entirely new network across an organization and its supply chain can seem daunting.

Most companies already have forecasting systems, and the data they collect can be highly valuable. However, that value differs when every company’s systems are internalized and separate from those of other companies in their supply chains.

The solution is to standardize how the supply chain as a whole collects, analyzes, and shares data. A blockchain network provides the trust and data privacy required to make that standard a reality for every company within the network. Data within a blockchain network is inherently trustworthy because no single entity has control of the data or business logic. The data is written within the blockchain and can’t be altered or tampered with once written in the network.

The significantly improved data quality leads to equally significant value when it comes to demand forecasting. Orders can be fulfilled on-time, every time, and manufacturers waste less material and product while still keeping customers happy. That’s because blockchain enables data safety and security, which affects demand forecasting in two important ways:

Blockchain’s most fundamental value is the ledger of data that it creates and makes accessible to every member within your supply chain network. It allows all parties to have control over what data they share through an encrypted chain and to manage who has access to that data both online and offline.

The data you share is shared across the entire network, where every permissioned member can view it on his or her own ledger. No single entity, or even group of entities, can change or alter the data without every other member knowing. This blankets all data in the network with a level of security and trust that was previously impossible to attain.

Data regarding sales, inventory, manufacturing, and more are essential to the accuracy of your demand forecasting efforts, but many companies worry about risks of sharing more than they should. However, integrating blockchain technology doesn’t necessarily mean giving up control of all data or the legacy systems that house it.

Companies that collect high-value customer data may have the most valuable forecasting information but may also wish to leverage that data in new ways. Within a blockchain network, they can more securely share information on a permissioned basis without losing control over it and can even track the use of the data in order to effectively manage compensation for its use.

The key to solving your demand forecasting problems is to improve data integration from all parties within your supply chain. Blockchain provides the solution for companies to do so with optimal privacy and without losing any proprietary data. To learn more about how blockchain can improve your supply chain process, download our whitepaper